- #INKSCAPE GCODE OUTPUT EXTENSTION HOW TO#

- #INKSCAPE GCODE OUTPUT EXTENSTION CODE#

- #INKSCAPE GCODE OUTPUT EXTENSTION DOWNLOAD#

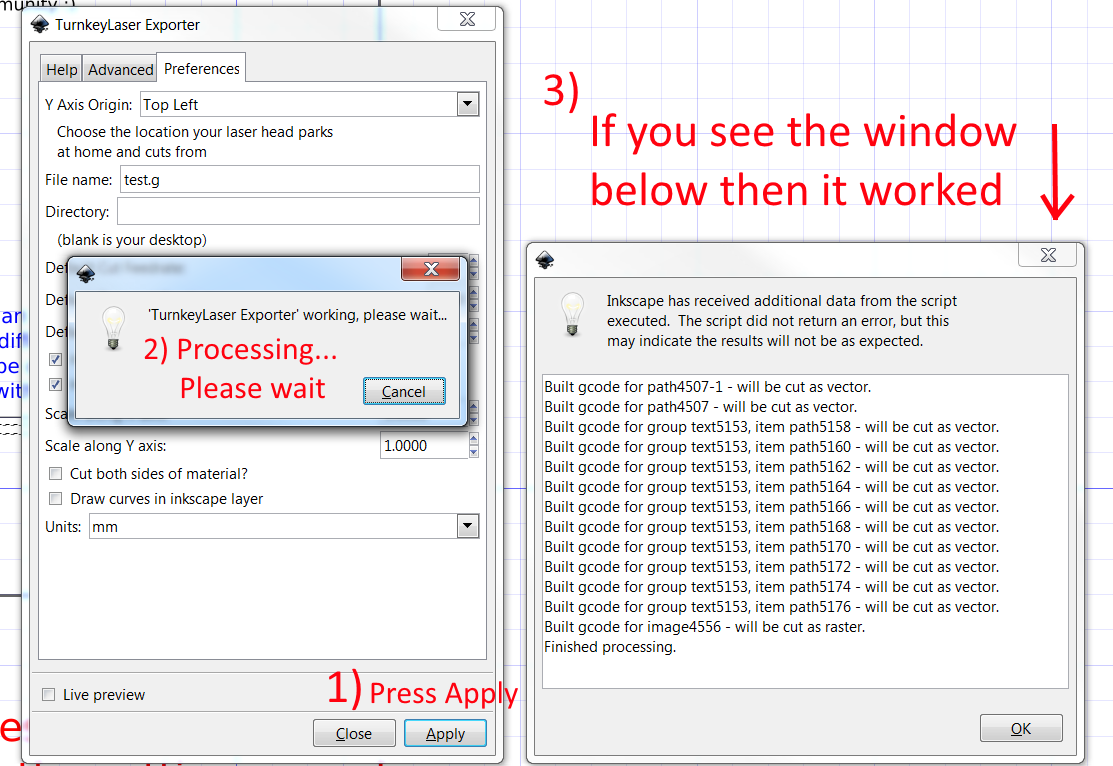

Now when you restart Inkscape, a new extension should pop up called MI GRBL Z-AXIS Servo Controller.įrom the guide, here are the steps for generating G-code: Extract the previously downloaded folder and copy all the files inside into your extensions folder for Inkscape. To use MIGRBL, you will need the MIGRBL extension made for Inkscape.

#INKSCAPE GCODE OUTPUT EXTENSTION HOW TO#

Here is a little diagram that shows you how to connect a servo to the GRBL CNC shield.Ĭonnect 5V and Ground to the corresponding pins on the GRBL CNC sheidl and then connect signal to the D11 pin or the Z+ End Stop Pin. Now, the connections for the servo motor is a little different.

#INKSCAPE GCODE OUTPUT EXTENSTION CODE#

Remember that when uploading code to the Arduino Uno, it can not be connected to the CNC shield or you will get a programmer error. Now in the Arduino IDE under examples>MIGRBL click the only example they have “grblUpload” and upload this code to your Arduino Uno. MIGRBL is the exact same as GRBL, so unzip this folder and import this library as you would with regular GRBL.

#INKSCAPE GCODE OUTPUT EXTENSTION DOWNLOAD#

You need to download the following two items: This method will utilize a modified GRBL firmware called MIGRBL to control a stepper motor in replacement of a spindle on a CNC machine. Using a guide on how control a servo motor with a GRBL CNC shield, I was able to get the servo integrated into the shield. However, with the dispenser mechanism using a stepper motor now, something with the CNC shield had to be done now. One of the reasons that Harri had tried to use the stepper motor previously, was due to the CNC shield not having support for a servo motor. This is the finished product with the replaced pieces and the cupcake batter dispenser almost no spillage now: CNC Shield ¶ Thus instead, Vincent suggested that the piece instead simply be flat on the top plane as there was no need for slopes. However, while the piece that blocked the nozzle sort of worked, lots of batter overflowed on the sides of the piece: Once we assembled the entire contraption, the entire thing fit very well. While PLA is not food safe, during actual use it will be covered in food safe plastic wrap to ensure there is no contamination in the batter. In addition to the servo mount, here is the piece that I will attach on the servo arm to block the nozzle of the cupcake dispenser: Thus, Harri and I created a CAD of a servo mount that would build off the already existing screws of the dispenser mount that Vincent Zhou created. To use this design, it was also mandatory that we create a mount dedicated for the servo. Without any servo or stepper motors powerful enough to push back the cupcake dispenser, an alternative solution was developed where the handle of the dispenser would be ziptied open and a servo with an arm would block the bottom of the dispenser. However, even this servo lacked in power and was unable to even inch the handle backwards. With tetrix frames, I created a temporary arm to test whether even this servo had enough torque to be able to push the cupcake batter dispenser.

It seemed there was too much resistance from the handle of the cupcake dispenser for the stepper motor to handle. However, before I started working on the mekanism, Harri ran into a few problems getting a smaller stepper motor to push the cupcake dispenser handle backwards. Individual Contribution ¶ Dispenser Mechanism ¶įor the group project, Harri Seto and I worked collaboratively on the dispenser mekanism and how we are going to squeeze the handle of the cupcake batter dispenser. document the group project and your individual contribution build the mechanical parts and operate it manually design a machine that includes mechanism+actuation+automation

0 kommentar(er)

0 kommentar(er)